Laser cleaning applications

A practical list of where laser cleaning (laser ablation) is commonly used — from heritage masonry to industrial maintenance. We focus on likely demand across London, Essex, Kent, Suffolk, Norfolk and surrounding areas.

Built environment & heritage

Brick, stone, concrete

Selective removal of surface deposits where blasting or chemicals are risky. Always test patches on porous surfaces.

- Graffiti removal and paint overspray

- Biological growth and ingrained grime

- Fire/soot staining (job-dependent)

Statues & detailing

Useful on irregular shapes, carvings and joints that other methods struggle to reach.

- Stone ornaments, plaques, memorials

- Delicate cleaning with strict stop-criteria

- Documentation for conservation work

Timber & features

Paint removal and surface prep on suitable timber and architectural details (test patches essential).

- Paint stripping on wood

- Door furniture and ironwork restoration

- Outdoor fixtures and fittings

Industrial, fabrication & maintenance

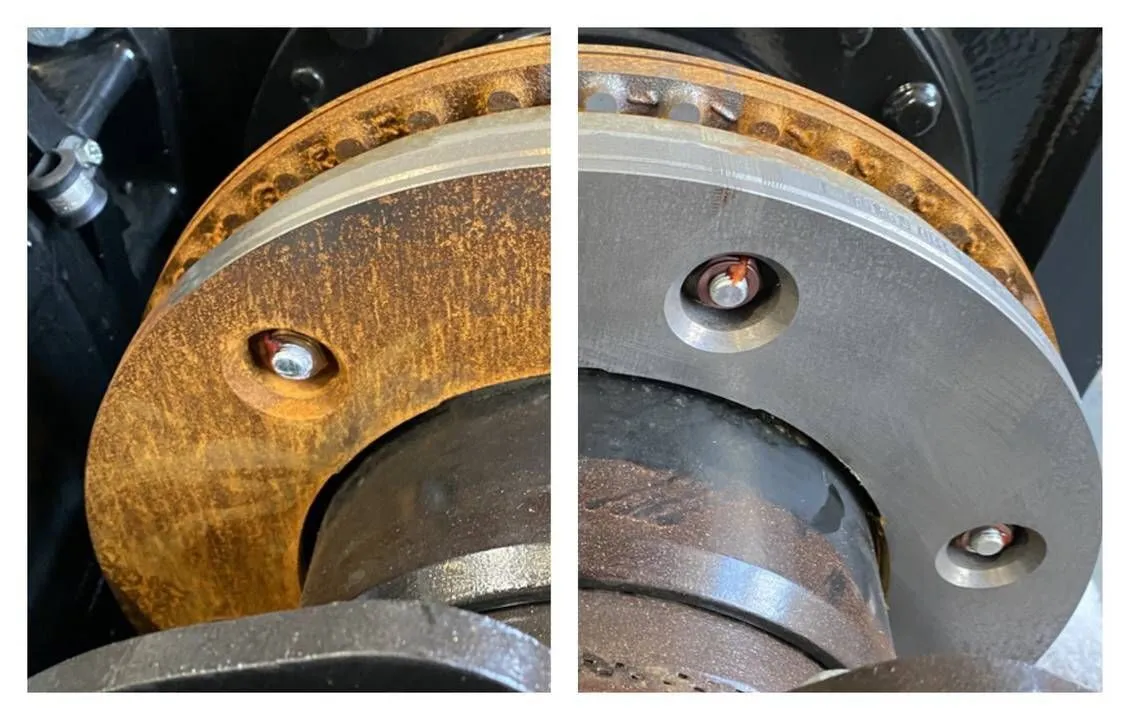

Rust & corrosion removal

A non-contact option for surface prep where preserving tolerances matters.

- Gates, railings, brackets, housings

- Surface prep before coating

- Localised corrosion on assemblies

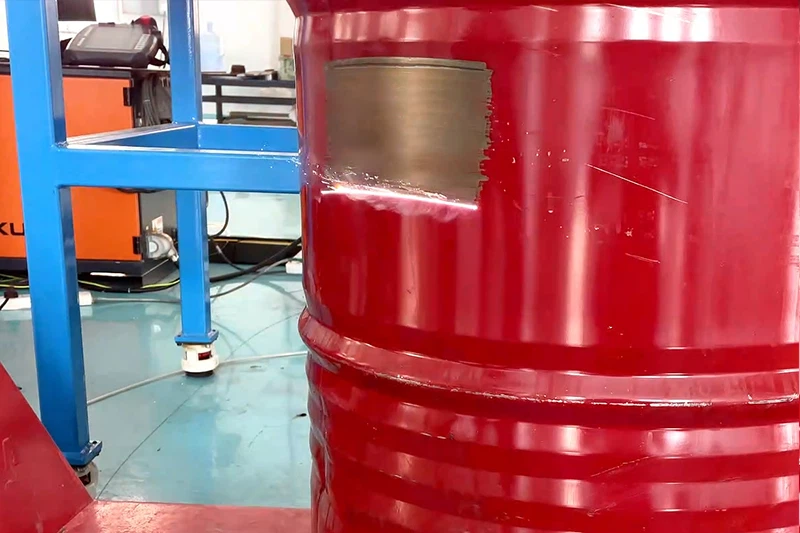

Paint & coating removal

Useful where you want controlled removal without blasting media.

- Selective stripping

- Preparation for rework and re-coating

- Residue management planning

Oils, grease, residues

Cleaning deposits from parts and fixtures where abrasives are undesirable.

- Degreasing-like surface cleaning

- Process residue removal (job dependent)

- Workshop maintenance

Automotive & restoration

Components and assemblies

When you want to preserve base material and avoid aggressive abrasion on parts.

- Brackets, housings, calipers

- Localised corrosion or coating removal

- Prep for paint where appropriate

Fixtures & antiques

Heirlooms and metalwork can often benefit from a controlled, test‑patch approach.

- Door furniture and knockers

- Decorative ironwork

- Careful cleaning on mixed materials

Other common use-cases

Grills & ovens

Removal of baked-on residues and aerosolised oils (site safety and ventilation planning required).

Corrosion management

Paint and corrosion work where controlling waste matters (job dependent and location dependent).

NDT preparation

Preparing weld areas without grinding away base material can help preserve integrity.

Want to discuss your specific surface?

Send us photos and a brief description and we’ll advise on suitability and availability.